REGIS Belt Splicing Structure – 3D Modelling and Fabrication Drawings

An expansive space that will straddle LA’s famed Wilshire Boulevard, the project will feature 110,000 square feet of gallery space in one single level to display and present art in a non-hierarchical, egalitarian way. As part of the new building, Clark will construct a new theater, education spaces, three restaurants, a museum shop, multi-purpose event spaces, and ancillary and back-of-house facilities.

The California Building for the Permanent Collection is slated to open to the public in 2024.

Client

California Building Co

Location

Los Angeles, California

Category

Construction & Engineering

Architect

Thomas Smith Studio

Year Completed

2024

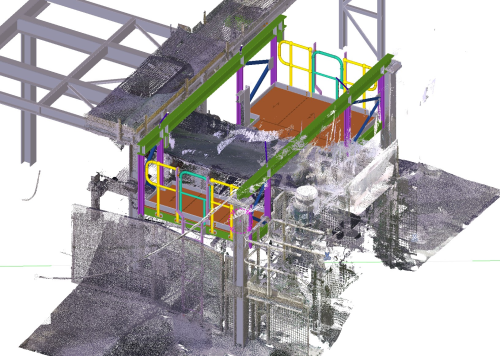

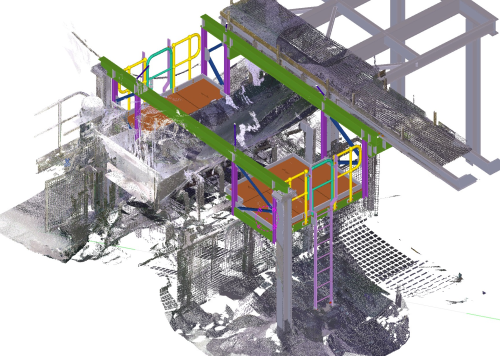

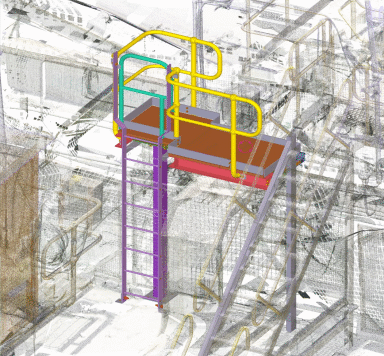

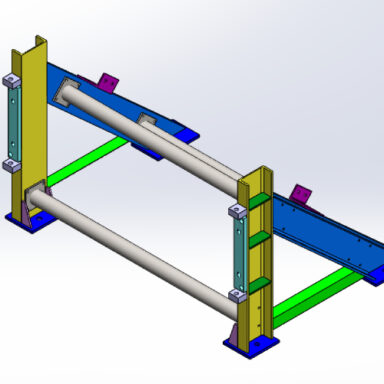

REGIS Belt Splicing Structure – 3D Modelling and Fabrication Drawings

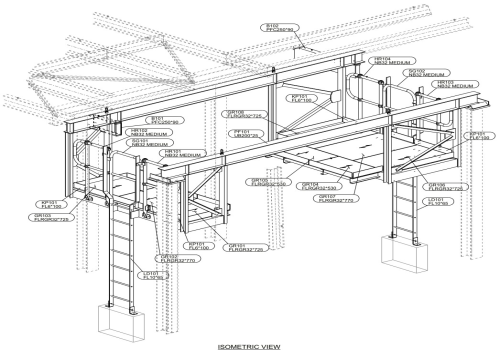

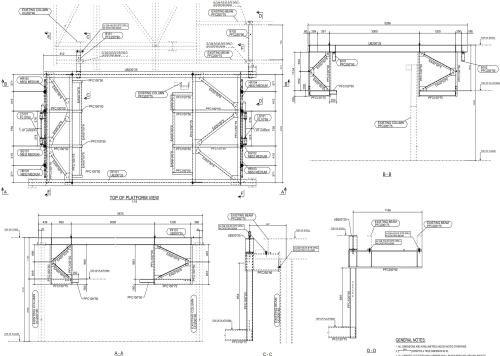

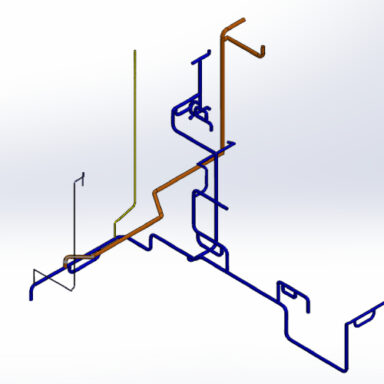

Our team was tasked with delivering detailed fabrication drawings and a 3D model for the REGIS Belt Splicing platform, using the client’s input as the foundation. The project challenged us to devise a practical, installation-ready structure while overcoming real-world site constraints.

Our Approach

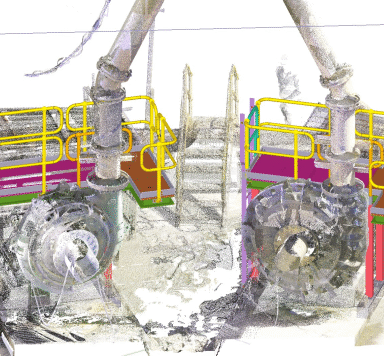

- Site Evaluation: We performed a focused site visit to assess conditions and identify installation limitations.

- Digital Surveying: Advanced 3D laser scanning captured the site with high accuracy for reference.

- Data Preparation:Scan data was meticulously processed to create an exact digital base.

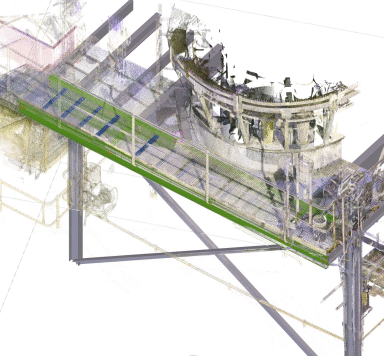

- Structural Design: Structural members were selected and precisely positioned in line with the site’s requirements.

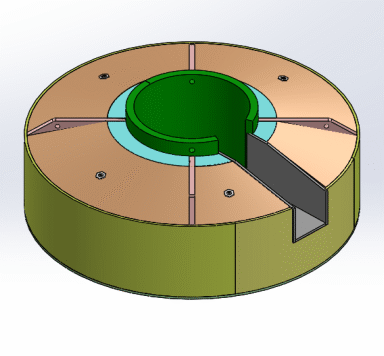

- 3D Modeling:A comprehensive platform model was built using professional software, incorporating client specifications.

- Connection Engineering: All structural connections were developed to meet project standards and installation best practices.

- Feature Integration: Key features such as handrails, grating, and ladder access were included for complete usability.

- Client Review: The digital model and drawings were presented for client input and approvals.

- Adaptive Engineering: To address on-site obstructions, we transitioned the design from a single welded assembly to modular bolted connections for easier installation.

- Final Submission: The full set of fabrication drawings was delivered ahead of schedule.

Outcome

The completed deliverables met every requirement with accuracy and efficiency. Our proactive problem-solving and attention to detail ensured a safe, efficient, and fully site-ready belt splicing platform, delivered on time and ready for construction.